L’industrie 4.0 est un terme qui reflète la 4éme révolution industrielle. Il se produit grâce aux incroyables progrès des technologies de l’information et de la robotique. Cependant, les entrepreneurs ne savent pas encore que le concept d’Industrie 4.0 peut améliorer considérablement leur productivité, la qualité de leurs produits et réduire également leurs coûts. La question est donc : Qu’est ce que vraiment l’industrie 4.0 ?

Dans cet article, les experts du Treakor (cabinet de conseil It) va vous donner tout ce qu’il faut savoir sur l’industrie 4.0 et comment la production s’est réinventée grâce cette nouvelle révolution industrielle. On commence !

Treakor : la meilleure équipe pour votre transformation digitale

Vous avez besoin d’un soutien pour votre transformation digitale ? Chez Treakor, nous vous accompagnons tout a long ce processus en vous apportant les meilleures conseils et solutions.

Veuillez consulter nos services tels que l’infogérance, conseil et audit it, consulting et intégartion SSI…

D’où vient le terme « industrie 4.0» ?

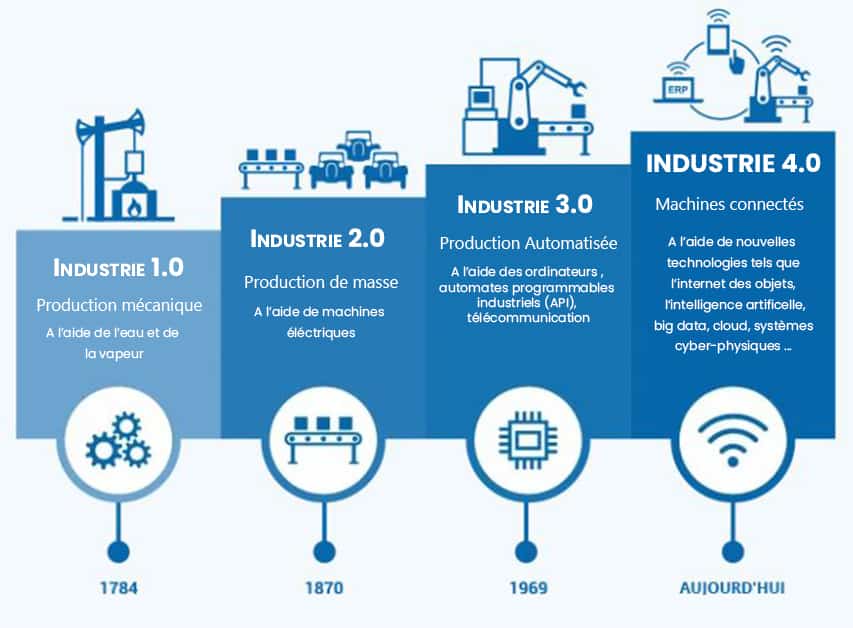

Au cours des dernières années, l’industrie a connu des avancées majeures qui ont de plus en plus transformé la façon dont les biens sont fabriqués et vendus. Ainsi, l’industrie 4.0 est arrivé dans la foulée des 3 révolutions et elle se caractérise par l’établissement d’une connectivité IoT entre les systèmes de production, les composants et les personnes. D’où, la naissance des usines intelligentes.

Qu’est que l’industrie 4.0 ?

Si les révolutions industrielles précédentes se fondait sur l’automatisation du processus de production, l’industrie 4.0 est une technologie qui consiste à piloter vos machines en temps réel et ainsi garder l’œil sur votre production. Cela devient possible suite à l’installation des capteurs à chaque étape du processus de production. De cette façon, vous pouvez prévenir les anomalies, recevoir des alertes et procéder à la maintenance des machines en cas de pannes. Ainsi, l’industrie 4.0 a contribué à réduire voire éliminer complétement les temps d’arrêt et donc à accélérer la production.

Quels sont les apports de l’Industrie 4.0 aux entreprises ?

Grâce aux récents développements technologiques, il est maintenant plus facile et plus économique pour les entreprises, PME ou PMI, d’investir dans les technologies 4.0. Ceux-ci améliorent l’efficacité et la rapidité du processus de production, la gestion des stocks, le délai de mise sur le marché, la flexibilité et, finalement, la sécurité de l’environnement de travail.

Principales technologies sur lesquelles se base l’Industrie 4.0

Internet des objets (IoT)

L’Internet des objets (en anglais : Internet of Things / IoT) désigne un ensemble d’objets connectés les uns aux autres via Internet. Ces objets peuvent recevoir et transmettre des données sans l’intervention de l’être humain.

Systèmes cyber-physiques (CPS)

En gros, les systèmes cyber-physiques (CPS) sont des engins monitorés par des ordinateurs afin de contrôler des entités physiques. Les véhicules autonomes ( exemple : Tesla) est un exemple de ces types de systèmes.

Big Data et analyse de données

Le Big Data est le moyen de gérer une énorme quantité de données qui se produisent de façon continue. L’objectif est de pouvoir tirer des conclusions permettant de mieux générer les affaires.

Cloud computing

Le cloud computing fournit des ressources (stockage, puissance de traitement, analyse…) qui peuvent être accédés à distance via internet.

Cabots

Les cobots sont des robots collaboratifs conçus pour libérer les opérateurs des tâches répétitives, complexes et dangereuses.

5G

Même si elle n’est pas encore répandue, la connexion 5G facilitera l’usage de l’IOT (Internet of things) et augmentera le niveau de portée entre les objets connectés. Cela permet une marge de manœuvre plus large et une efficacité meilleure dans les usines.

Exemples d’applications de l’industrie 4.0?

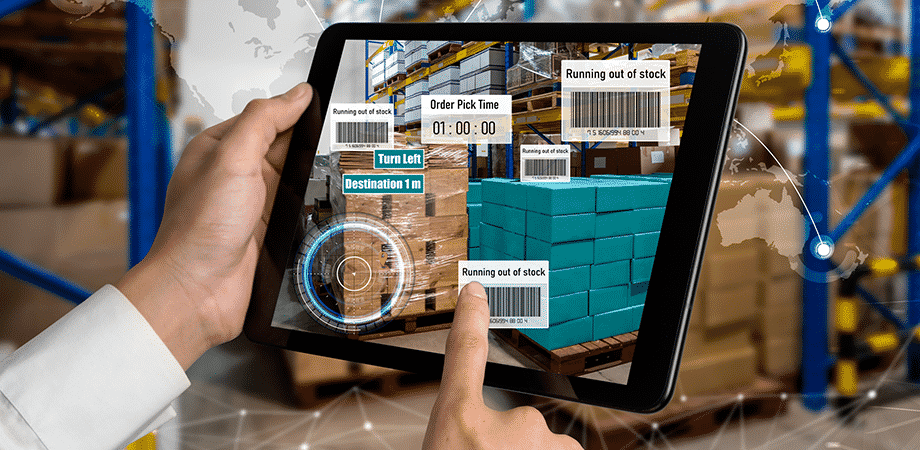

- Surveiller et contrôler en temps réel les machines : En installant des capteurs sur vos machines, vous pouvez suivre votre production, collecter des données en temps réel, corriger les problèmes et prendre les meilleures décisions stratégiques.

- Se débarrasser des supports papiers : En optant pour l’industrie 4.0, tous les documents commerciaux (instructions, spécification de produits, bons de commande, etc.) d’une entreprise deviennent numériques.Cela aide les entreprises à réduire les erreurs causées par des données erronées et à économiser du temps et de l’argent.

- Bénéficier des machines intelligentes : A l’ère de l’industrie 4.0, les machines sont devenus capables d’analyser leurs propres données, de prédire quand elles doivent étre réparées et prendre même des rendez-vous avec un technicien. Impressionnant !

- Optimiser le processus de production : A travers l’exploration de données, Vous pouvez repérer les meilleurs scénarios de production et servez-vous de ceux-ci pour optimiser l’utilisation de vos actifs, améliorer la production et ainsi réduire les coûts.

Les défis et les opportunités de l’industrie 4.0 :

L’un de défis majeurs auxquels l’industrie 4.0 sera confrontée dans les prochaines années, est la mise en danger des millions d’emploi (40% de la totalité d’emplois existants) causé par les avancés dans les domaines de l’automatisation et la robotique. Les robots peuvent aujourd’hui remplacer les êtres humains et effectuer les tâches les plus complexes et les plus dangereuses.

Cependant, la 4éme révolution industrielle a contribué à ouvrir de nouvelles perspectives et à créer un nombre important d’opportunités, notamment dans les domaines de big data, de cybersécurité, de blockchain, du cloud computing, etc.